Li-brushes tsa carbon ke likarolo tse thellang tsa li-motor kapa lijenereithara tseophetisojwale ho tloha dikarolong tse emeng ho ya ho tse potolohang. Ka li-motors tsa DC, li-brush tsa carbonka fihlamotsamao o senang tlhase. Morteng carbon brushes kaofela li etsoa ka boikemelo keeonaSehlopha sa R&D, se apereng hantleng, lubricity e babatsehang, ts'ebetso e tsitsitseng. Ea ronaborashe ba carbon e ka khonaho etsoa le ho etsoa customized hoho fihlela litlhoko tsa masimo le maemo a fapaneng a ts'ebetso. Li-brushes tsa rona tsa carbon li loketse matla a moea, matla a mocheso, matla a metsi, tšepe, merafo, thapo, mechine ea kaho, pampiri, samente, electroplating, lipalangoang tsa terene le masimo a mang.

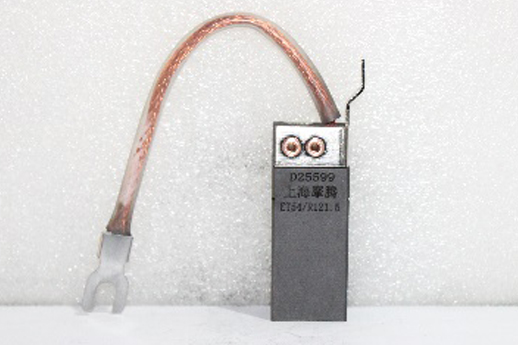

Carbon brush e ka ba le:

E le 'ngoe kapa ho feta graphite blocks

Mohala o le mong kapa ho feta

Borushana ba carbon bo bohlokoa haholo mochineng. E le hore re sebelise karolo ea eona ka botlalo, re lokela ho hlahloba lintlha tse tharo tsa sehlooho:

Litlhophiso:

Mechanical parameters

Litekanyetso tsa motlakase

Mekhahlelo ea 'mele le ea lik'hemik'hale (tikoloho).

Ka ho kopanya lintlha tsa tekheniki tse fanoeng ke moreki le li-parameter tse kaholimo, litsebi tsa rona li ka khetha lisebelisoa tse loketseng ka ho fetisisa tsa carbon brush ho fihlela kopo ea moreki.

Sehlopha sa rona sa litsebi se tla eletsa moreki mabapi le mokhoa oa ho ntlafatsa liparamente tsa enjene ho ntlafatsa boleng ba ts'ebetso ea koloi le mekhoa ea ho e lokisa. Ka boiteko bo kopanetsoeng ba mahlakore ka bobeli, lisebelisoa tsa moreki li tla ntlafatsoa ts'ebetsong le bophelo ba tšebeletso bo tla atolosoa.

Morteng brush tšobotsi:

Ka mokhoa o ikhethileng oa ho fihlela ts'ebetso e tšepahalang

Bokhoni ba ho etsa filimi ea oxide e tsitsitseng, khohlano e tlase.

Bokhoni bo eketsehileng ba ho khutlisa tlhase, ho fihlela sekhooa se senyenyane sa carbon brush.

Liaparo tse nyenyane tsa carbon brush, li finyella ts'ebetso e tsitsitseng haholoanyane

Ke hobane'ng ha u re khetha?

Tlhahiso e ruileng ea brashi ea carbon le boiphihlelo ba ts'ebeliso

Lipatlisiso tse tsoetseng pele le nts'etsopele le bokhoni ba moralo

Sehlopha sa litsebi sa tšehetso ea tekheniki le ts'ebeliso, se ikamahanya le maemo a fapaneng a rarahaneng a ho sebetsa, a hlophisitsoeng ho latela litlhoko tse khethehileng tsa bareki.

Tharollo e ntlafetseng le e akaretsang, ho apara le ho senyeha ho fokolang ha bapalami

Sekhahla se tlase sa ho lokisa likoloi

Nako ea poso: Aug-30-2022