Main Carbon Brush CT53 bakeng sa GE Suzlon Siemens Nordex turbine

Tlhaloso ea Sehlahisoa

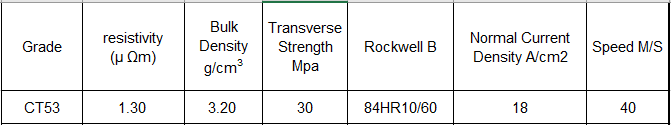

| Mofuta oa Carbon Brush le boholo | |||||||

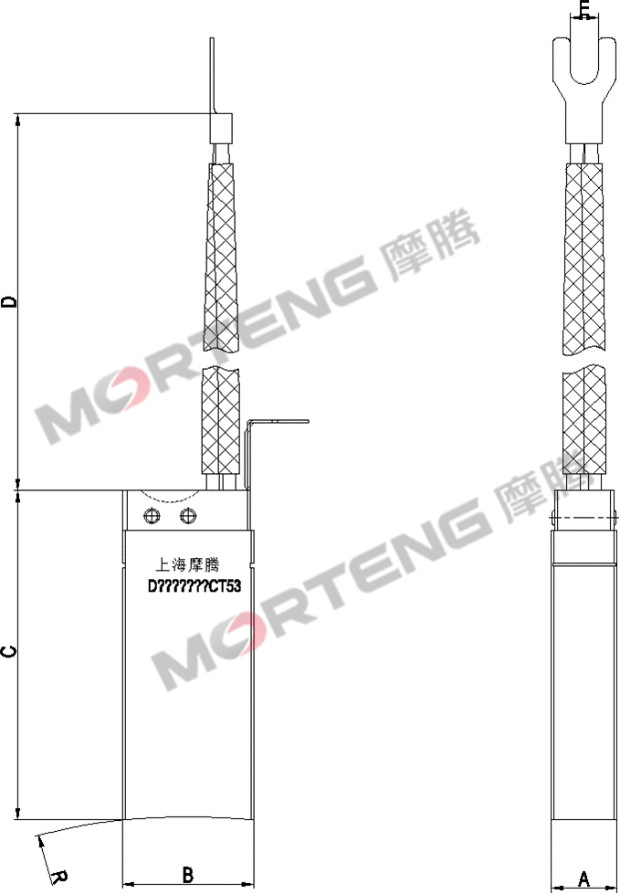

| Setšoantšo sa No | Kereiti | A | B | C | D | E | R |

| MDFD-C200400-138-01 | CT53 | 20 | 40 | 100 | 205 | 8.5 | R150 |

| MDFD-C200400-138-02 | CT53 | 20 | 40 | 100 | 205 | 8.5 | R160 |

| MDFD-C200400-141-06 | CT53 | 20 | 40 | 42 | 125 | 6.5 | R120 |

| MDFD-C200400-142 | CT67 | 20 | 40 | 42 | 100 | 6.5 | R120 |

| MDFD-C200400-142-08 | CT55 | 20 | 40 | 50 | 140 | 8.5 | R130 |

| MDFD-C200400-142-10 | CT55 | 20 | 40 | 42 | 120 | 8.5 | R160 |

Moralo & tšebeletso Customized

Joaloka moetsi ea ka sehloohong oa borashe ba khabone ea motlakase le litsamaiso tsa mehele e thellang naheng ea China, Morteng o bokelletse theknoloji ea profeshenale le boiphihlelo bo bongata ba litšebeletso. Ha re khone feela ho hlahisa likarolo tse tloaelehileng tse finyellang litlhoko tsa bareki ho ea ka maemo a naha le a indasteri, empa hape re fana ka lihlahisoa le litšebeletso tse hlophisitsoeng ka nako e loketseng ho latela indasteri ea bareki le litlhoko tsa kopo, le ho rala le ho etsa lihlahisoa tse khotsofatsang bareki. Morteng e khona ho fihlela litlhoko tsa bareki ka botlalo le ho fa bareki tharollo e phethahetseng.

Ha o ikopanya le rona ho odara borashe ba khabone, ka kopo fana ka lintlha tse latelang

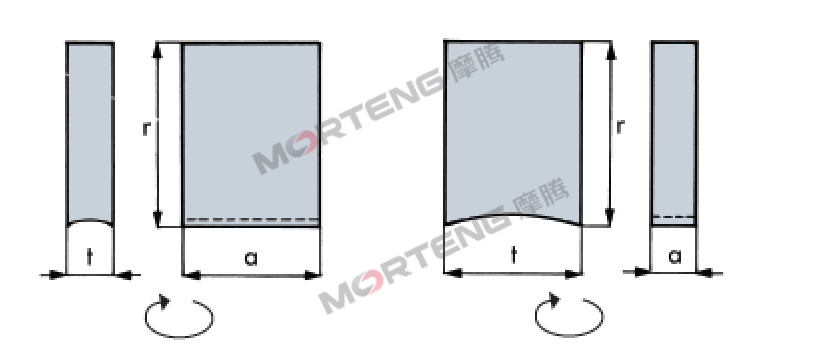

Litekanyo tsa borashe ba carbon li hlahisoa e le “t” x “a” x “r” (IEC norm 60136).

• "t" e bolela boholo ba tangential kapa "botenya" ba carbon brush

• "a" e bolela "axial dimension" kapa "bophara" ba carbon brush

• "r" e bolela boholo ba radial kapa "bolelele" ba carbon brush

"r" litekanyo ke tsa litšupiso feela

Melao ea tlhaloso ea boholo bakeng sa borashe ba carbon e boetse e sebetsa ho bapalami kapa li-slip rings.

Ka kopo ela hloko phapang pakeng tsa borashe ba k'habone le boholo ba lisenthimithara tsa carbon, ho bonolo ho ferekanngoa (1 inch e lekana le 25.4mm, 25.4mm le 25mm)

li-brushes tsa carbon mm ha li lekane).

"t", "a" le "r" litekanyo

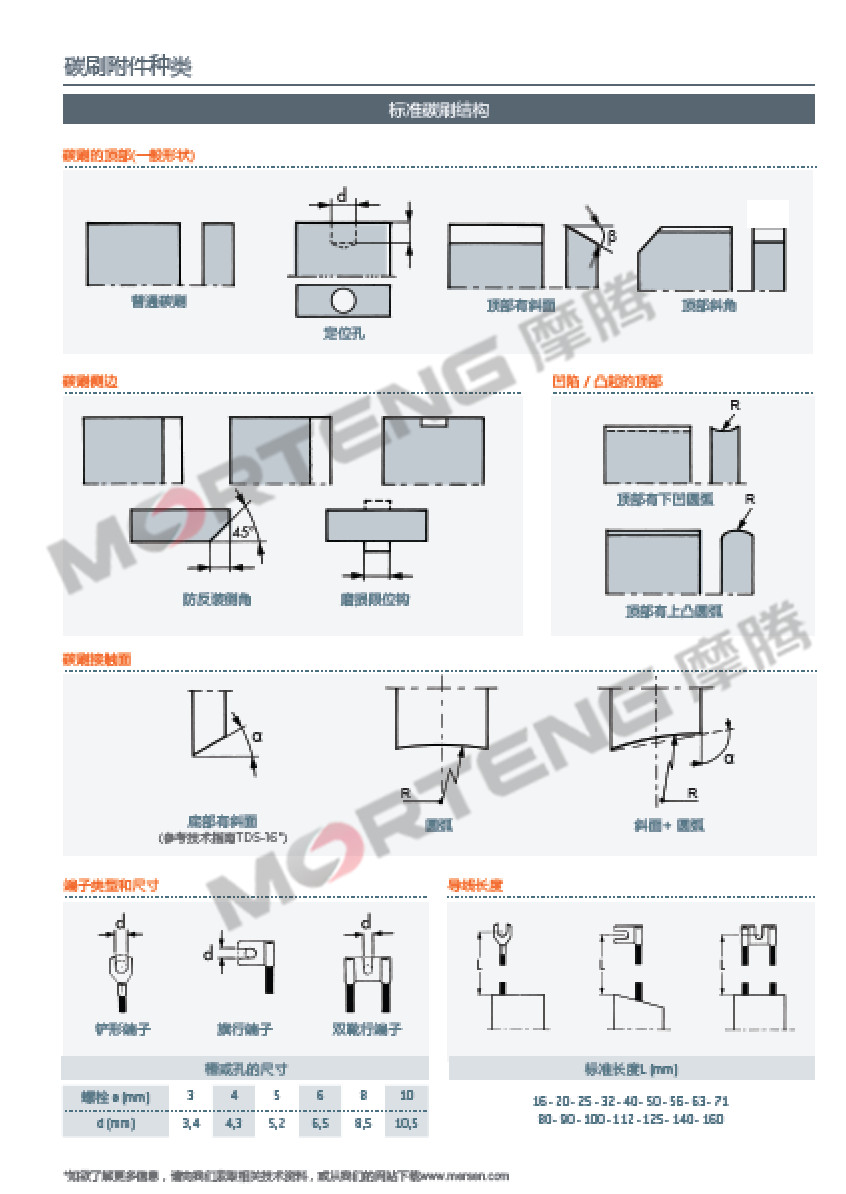

Sebopeho sa brashi ea carbon e nang le sebōpeho se sa fellang

Kenyelletso ea Khampani

Morteng ke moetsi ea etelletseng pele oa ho ts'oara borashe, brashi ea khabone le kopano ea li-slip ring ka lilemo tse 30. Re nts'etsapele, re rala le ho etsa tharollo ea kakaretso ea boenjiniere bakeng sa lik'hamphani tsa lits'ebeletso, barekisi le li-OEM. Re fa bareki ba rona theko ea tlholisano, boleng bo holimo, lihlahisoa tsa nako ea ho etella pele ka potlako.

Litlhahiso tsa ho kenya borashe ba carbon

Litlhahiso tsa rona ke tsena:

1. Kopanya borashe ba k'habone ea lisebelisoa tse fapaneng bakeng sa enjene e le 'ngoe ka statically ho qoba liphoso tse tebileng.

2.Ho fetola thepa ea carbon brush e tlameha ho netefatsa hore filimi e teng ea oxide e tlosoa.

3.Hlahloba hore li-brush tsa carbon li ka thella ka bolokolohi ka har'a mokotlana oa borashe ntle le tumello e feteletseng (sheba Tataiso ea Teknoloji TDS-4 *).

4. Hlahloba ho etsa bonnete ba hore mokhoa oa li-brush tsa carbon ka lebokoseng la borashe o nepahetse, ela hloko ka ho khetheha li-brushes tsa carbon tse nang le li-bevel holimo kapa ka tlaase, kapa li-brush tsa carbon tse arohaneng tse nang le li-gaskets tsa tšepe holimo.

Ho sila pele ho sebaka sa ho kopana le borashe ba carbon

E le ho lumellana hantle le sebaka sa ho kopana le carbon brush le arc ea ring slip kapa commutator, carbon brush pre-grinding lejoe le ka sebelisoa ka lebelo le tlaase kapa le se na mojaro. Phofo e hlahisoang ke grindstone ea pele ho fatše e ka etsa kapele arc e nepahetseng ea carbon brush contact surface.

Ho boetse hoa hlokahala ho sebelisa grindstone ea lijo-thollo tse mahareng ka mor'a ho sila pele.

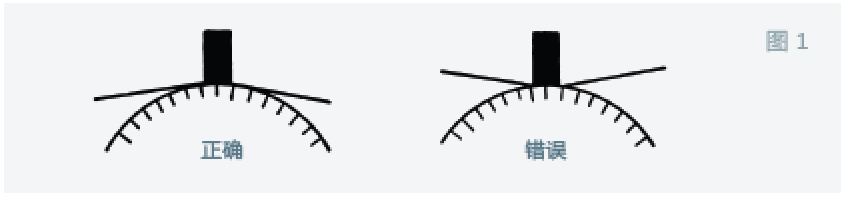

Haeba palo ea ho sila pele e batla e le kholo, ho molemo ho sebelisa sandpaper e ntle ea 60 ~ 80 mesh bakeng sa ho sila ka thata. Ha o sila ka thata, beha sefahleho sa sandpaper hodimo pakeng tsa borashe ba carbon le motor commutator, ebe o isa sandpaper pele le morao ka makgetlo a mmalwa, jwaloka ha ho bontshitswe ho Setšoantšo sa 1.

Ka mor'a hore carbon brush pre-grinding e phethoe, sebaka sa ho kopana sa carbon brush se lokela ho hloekisoa hantle, 'me lehlabathe lohle kapa phofo ea carbon e lokela ho felloa ke moea.